Rotax Squish Gap Check - 587/657/717/787/947

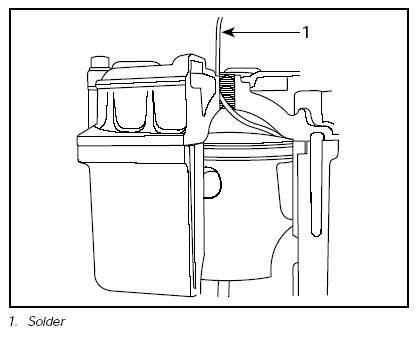

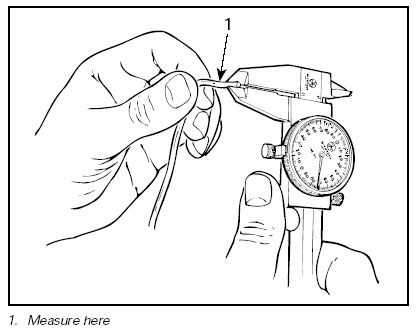

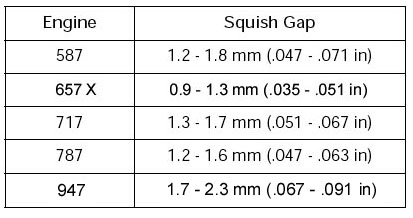

Whenever rebuilding the top end of a Rotax 2 stroke, a very important step is setting the "Squish Gap". It involves assembling the shortblock, inserting a piece of solder in each plug hole, turning engine and seeing how thick solder is. If not in tolerance, motor is disassembled and thinner/thicker base gasket is installed. If you don't check and the gap is out of spec, serious engine damage can occur. Specifically, if the gap is too large, a loss of power will occur and too small will lead to detonation.

I check squish gap before installing the rings to make it a little easier but thatís your choice. If you check it with the rings installed and using the same thickness gasket as was removed then assemble it properly before checking gap, you can just torque everything down if you find itís in spec instead of taking it back apart to install the rings. Also, remember to tell what thickness base gasket you have, count the holes. A 6 hole gasket corresponds to 0.6mm.